![]()

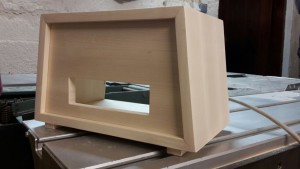

A good friend of the older generation of technicians is certainly the analog multimeter of the manufacturer Unigor. In this case, it is the model Unigor_6e from the 70s.

An excerpt from the preface of the operating manual:

The electronic instrument Unigor 6e combines the advantages of classical measuring technology with those of modern electronics.

It was specially developed for measurements in the field of electronics and for all those applications where practically no power is required. The high sensitivity is achieved by means of a battery-powered transistor amplifier.

The field effect transistor chopper for DC measurements and the multiple negative feedback guarantee high stability and negligible drift. The large measuring range and the high accuracy of 1% at AC and DC, allows universal use in the radio and television service in test field and laboratories.

The “6e” offers a total

- 54 DC and AC / voltage ranges

- 13 dB ranges

- 12 resistance and capacity ranges

- 2 temperature ranges

The electronic components of the meter are powered by four 1.5V batteries and take a current of about 2.5mA. The working range of the electronics is between 4V and 7V. The battery is switched on with the rotary switch (which also represents the R, C adjustment knob at the same time). To check the battery voltage, a check position is provided on the measuring range shutter.

The Unigor 6e also offers a variety of protective devices and is therefore protected against damage caused by incorrect handling and overload. (I can remember quite well from my school time that this is not always the case: D)

The Unigor 6e has an electromechanical circuit breaker function. Its relay responds to overloads with DC and AC and requires no auxiliary power. The protection therefore remains fully effective even when the battery switch or battery is switched off. The restarting in case of permanent overload is prevented by a special switching mechanism.

Furthermore, fuses provide protection at the higher current ranges to respond in the event of a short circuit or tripping of the circuit breaker.

Against overvoltages at the inputs are voltage arresters at the input terminals whose breakdown voltage is lower than that of the internal circuit.