![]()

“Freshly mopped floors without having to vacuum beforehand: The FC 7 Cordless hard floor cleaner removes all types of dry and damp everyday dirt in one step.” (Original text kaercher.com)

You get this product promise on the manufacturer’s website if you are interested in the FC7 electric hard floor cleaner. However, when this promise is no longer kept, I find out about the existence of these appliances. Because then I am asked to check why something is no longer working as it should. This is also the case here. The brushes (rollers – whatever these parts are called) no longer rotate, according to the problem description. Or to be more precise, they only turn sometimes when the bottom part of the moving handle is in a certain position. And since the handle (in which all the electronics such as batteries, BMS and operating elements are housed) can be moved within a wide range, it is reasonable to assume that there is a cable break or similar contact problem.

This is not exactly a complex problem, but perhaps one or the other is interested in how the problem can be solved with more or less effort.

The first step is to remove the wastewater tank and the four cleaning rollers. The screws on the drive cover and battery cover can then be loosened and the covers removed.

Once the covers have been loosened, they can be removed. The circuit board with the BMS and the control electronics of the device can be seen under the battery cover. The 18650 Li-Ion cells are located underneath. The outlets to the bottom drive, to the control unit in the handle, etc. are plugged in.

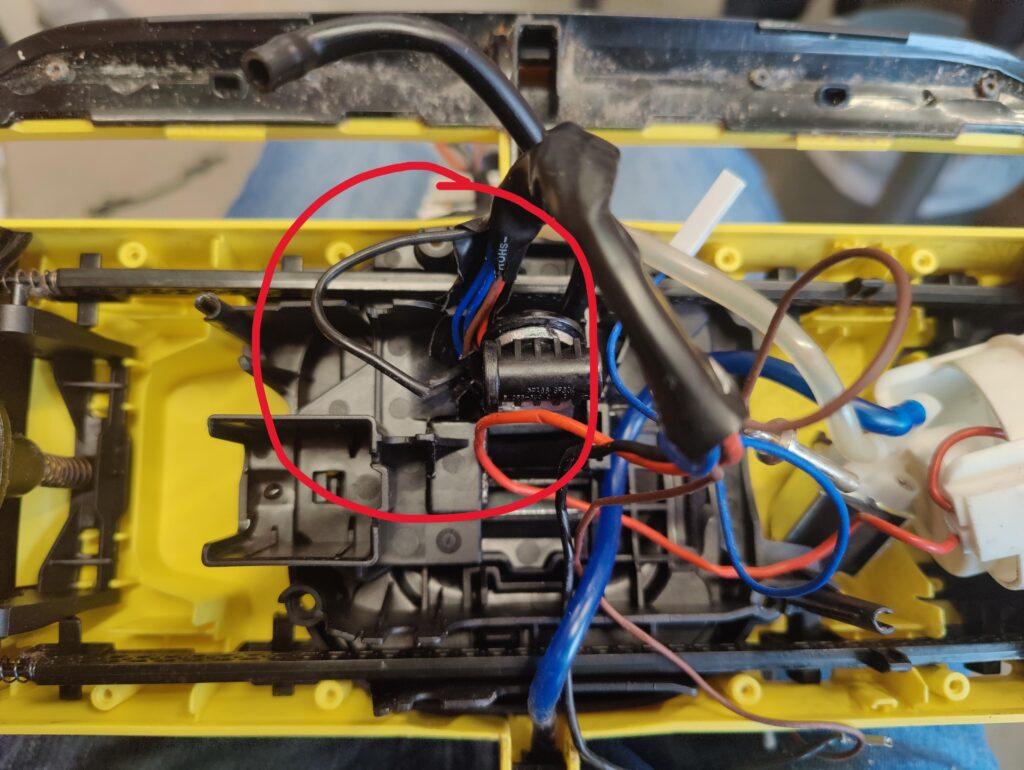

The eight-pin plug at the bottom left of the picture must be disconnected. It connects the brush drive to the electronics. Six of the eight pins of the plug are occupied. One red and one black wire are used to supply the DC motor (yes, only a DC brush motor has been installed here and not a brushless one …) and two brown wires are laid to the pins that form the resistance sensor for the water level in the dirty water tank. Two blue wires control the solenoid valve of the water inlet.

As the fault is in the motor drive (depending on the position of the handle, the motor may or may not turn), the fault may be in the cable connection from the circuit board to the motor. The fault was quickly discovered with the continuity test of the multimeter. The black cable to the motor was broken.

The breaking point is exactly in the area where the handle is movably attached to the floor unit. This is exactly where the wiring harness and the rubber hose for the water guide are inserted. Constantly moving the cable harness will inevitably damage and break the cables in the long term. Especially if the handle is used at very shallow angles, for example to clean the floor under boxes, chests of drawers, etc.

I did the repair here by soldering the wire together and protecting it with heat-shrink tubing. I wrapped the damaged cable protection conduit with insulating tape. This should hold for some time. As the part will not last forever due to its design, the wiring harness should be completely replaced during the next repair. (as this is probably not available as a spare part, you will probably have to make one yourself – but then with more stable, highly flexible wires…)

The components could now be reassembled. Place the rollers in the green/blue colors on the drive hubs and screw everything back together.

Broken cable connections and torn toothed belts in the motor unit are obviously the most common faults with this appliance.