![]()

This article has nothing to do with electronics. In my retro-madness I was once again rummaging in the cellar of the parents’ house and discovered there behind dusty jars of musty-smelling cardboard boxes with unknown content. So what was left to me to uncover and view the contents of these cardboard boxes? And what came out here were other boxes of the well-known toy manufacturer “LEGO”. Some very dusty original boxes of Lego-Technik models and old washing powder boxes, which were filled with many, many colorful Lego bricks and other stuff and unfortunately also garbage. Actually, I thought to myself, these many plastic parts I can throw in the trash, because that will not play my son safe. Everything smells like cellar and is dirty and the work, everything to clean and sort will certainly no longer hurt anyone. But on the other hand is the really old toy from the 70s and 80s – so over forty years old. And that is exactly mine again. 🙂 Things from my childhood and memories of it.

So packed everything and transported home. And then, in painstaking work, sorted everything once into colors and freed it from rubbish and lego-foreign parts. And now the real work began. The goal should be to put together from the many parts of the old Lego-Technik models and missing parts as far as still available to order. The “vintage kits” should be restored as well as possible in their originality.

The photo shows a small part of the “excavated” Lego boxes. At least the boxes were already roughly cleaned. What came out after the painstaking sorting and construction work, however, can also be seen again.

Nr. 853 Lego Car-Chassis

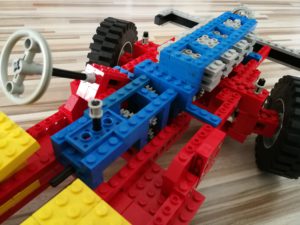

The number 853 is the car chassis. The kit was sold in the year 1977. It consists of 601 parts and finished construction about 52cm long and 22cm wide.

The number 853 is the car chassis. The kit was sold in the year 1977. It consists of 601 parts and finished construction about 52cm long and 22cm wide.

The model has a four-cylinder in-line engine with two-speed gearbox and cardan shaft to the rigid rear axle. The gearbox as well as the pistons are functional. Likewise, the steering works. The seats are displaceable in the longitudinal axis.

The model has a four-cylinder in-line engine with two-speed gearbox and cardan shaft to the rigid rear axle. The gearbox as well as the pistons are functional. Likewise, the steering works. The seats are displaceable in the longitudinal axis.

In this series, the rear axle was still rigid and equipped with a differential. The following picture shows the tidy, restored kit.

Nr.: 8860 Car Chassis

Out of 671 individual parts, the car is to assemble chassis number 8860. The set dates from the year 1980 and has a size of 46×19 cm. Here was compared to the 853er already much expanded. The rear wheels are hung individually and have a suspension. The engine sits behind and this time is a four-cylinder boxer. Again, there is a transmission with three stages.

The seats are adjustable in the longitudinal direction and the inclination of the seat back can also be adjusted. Again, a rack and pinion steering is installed.

The original packaging is still available and looks like this in the sorted condition:

Nr. 854 Lego GoKart

From 1978 comes the Lego GoKart No. 854. It has the dimensions of approximately 21 x 13cm and is composed of 206 parts. On realized functions there is a rack and pinion steering and a single-cylinder engine, with a functional piston. The rear axle is rigid and the shaft is connected via a transmission with the crank of the piston. According to data in the network, this model has now reached cult status, as it should be one of the first Lego-technology models ever. Here is the original packaging and especially the number 9 on the front still available, then the model in collector’s circles should be really valuable. Unfortunately, I can not meet either criterion.

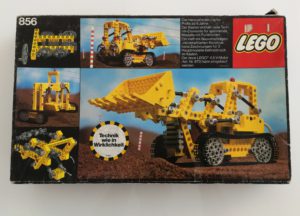

Nr. 856 Lego Bulldozer

With the model no. 856, Lego has launched one of the countless construction vehicle models on the market. The bulldozer dates back to 1979 and consists of 370 parts. The base is 24x 11cm at a height of 14cm. Of the functions of the blade is tiltable, raised and lowered. Two chains on gears represent the connection to the bearing surface.

Unfortunately, here too, only the box without internal division is available from the original packaging.

Nr. 8848 Lego Unimog

The Unimog 8848 from the year 1981 measures just under 30x12cm at a base of 14cm. It consists of 398 parts. As a functioning technology here again the steering, the tilting cargo area, as well as a raised and lowered, and tiltable bucket available.

Unfortunately, the box is missing the interior, otherwise the model is complete. Apart from the here presented, complete kits are still some more available, but where unfortunately too many parts missing. But some flea market or online raid of lego parts will probably arise once again to complete these sets and to be able to fully incorporate them into a retrospective collection.

Unfortunately, the box is missing the interior, otherwise the model is complete. Apart from the here presented, complete kits are still some more available, but where unfortunately too many parts missing. But some flea market or online raid of lego parts will probably arise once again to complete these sets and to be able to fully incorporate them into a retrospective collection.