![]()

|

| the finished machine |

As a gift I received in the winter of 2014 a kit for a model of a Stirling hot air machine. The design plans, as well as the largely prefabricated parts, come from Mr. Klaus Künneth, the operator of the website www.kk-stirlingmotor.de

To build and install only a little manual skill and a few gauges and tools are needed. (Stand drill, drill and tap, a grinding block with polishing wheels, at least a sliding calliper, a little clear coat and machine oil). On some parts holes of various diameters are to be made. For example, on the flywheel, the connecting rods. In the cylinder and head cover, the mounting holes are to drill and thread to cut.

|

| drill the flywheel |

After preparing all the items, everything is polished to a high gloss on the polishing machine. Then you can start with the assembly. All in all, one should take a few hours to have the model beautiful, meticulous and functional. From a few parts is then also quickly made a small spirit burner, which provides the necessary heat for operation under the working piston. Everything together is then mounted on the clear lacquer-sealed wooden base plate.

|

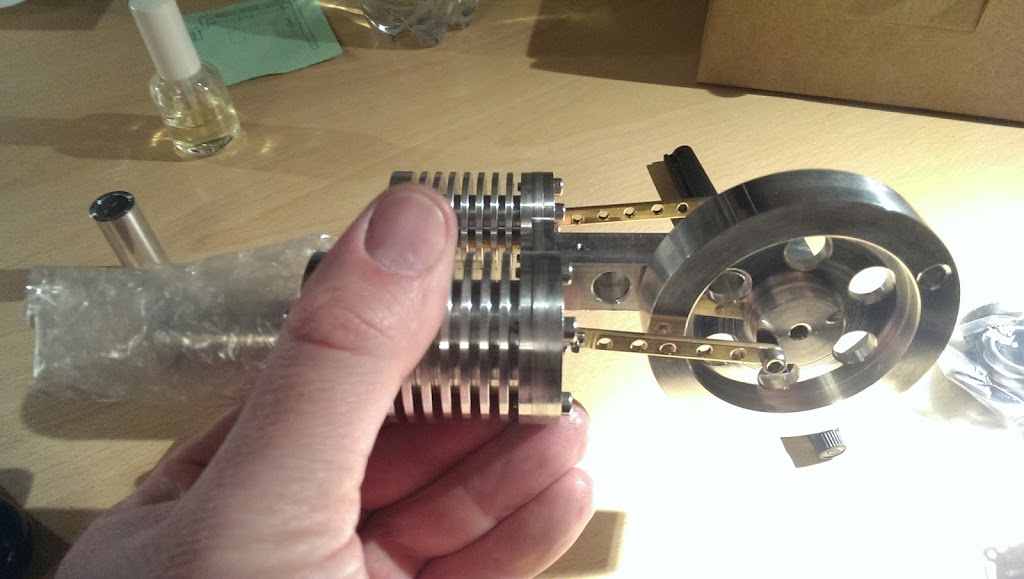

| finished polished unit |