The goal was to build a BLCD Motor Test-Stand to measure how electric current and buoyancy are changing on several different motor propeller combinations. The motor/props tests are mainly focused for usage with Quadrocopter like vehicles. Furthermore Amir (Godfather of Quadrocopters)

came up with the idea to measure the Tau63 for the PT1 transmission behavior.

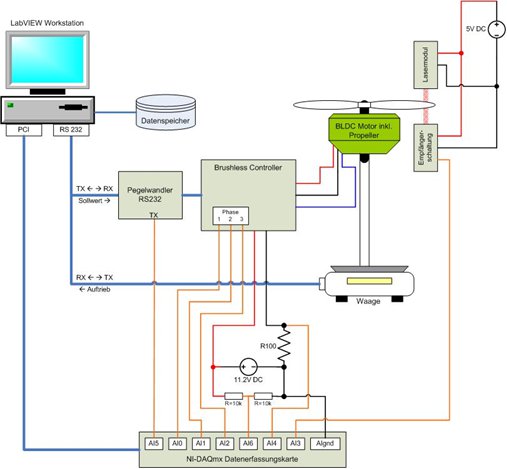

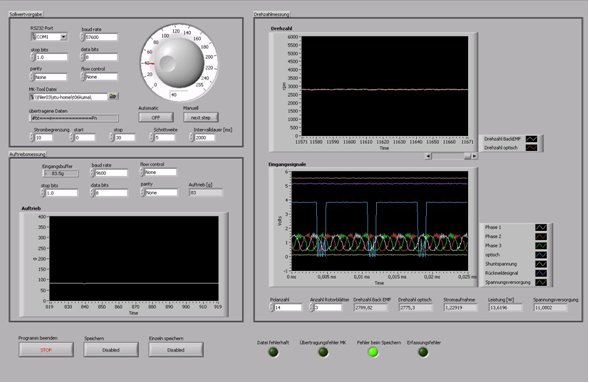

The software part is entirely written in G (LabVIEW). For data acquisition we used the NI PCI-6024E interfaced via DAQmx.

With DAQmx you can set up your measurement hardware very easily (see next snippet).

Measured signals are:

Sampling rate = 10kHz

- BLC- Ctrl. Phase 1

- BLC- Ctrl. Phase 2

- BLC- Ctrl. Phase 3

- motor speed with optical sensor

- power input

- command acknowledge from BLDC-Controller

- voltage supply

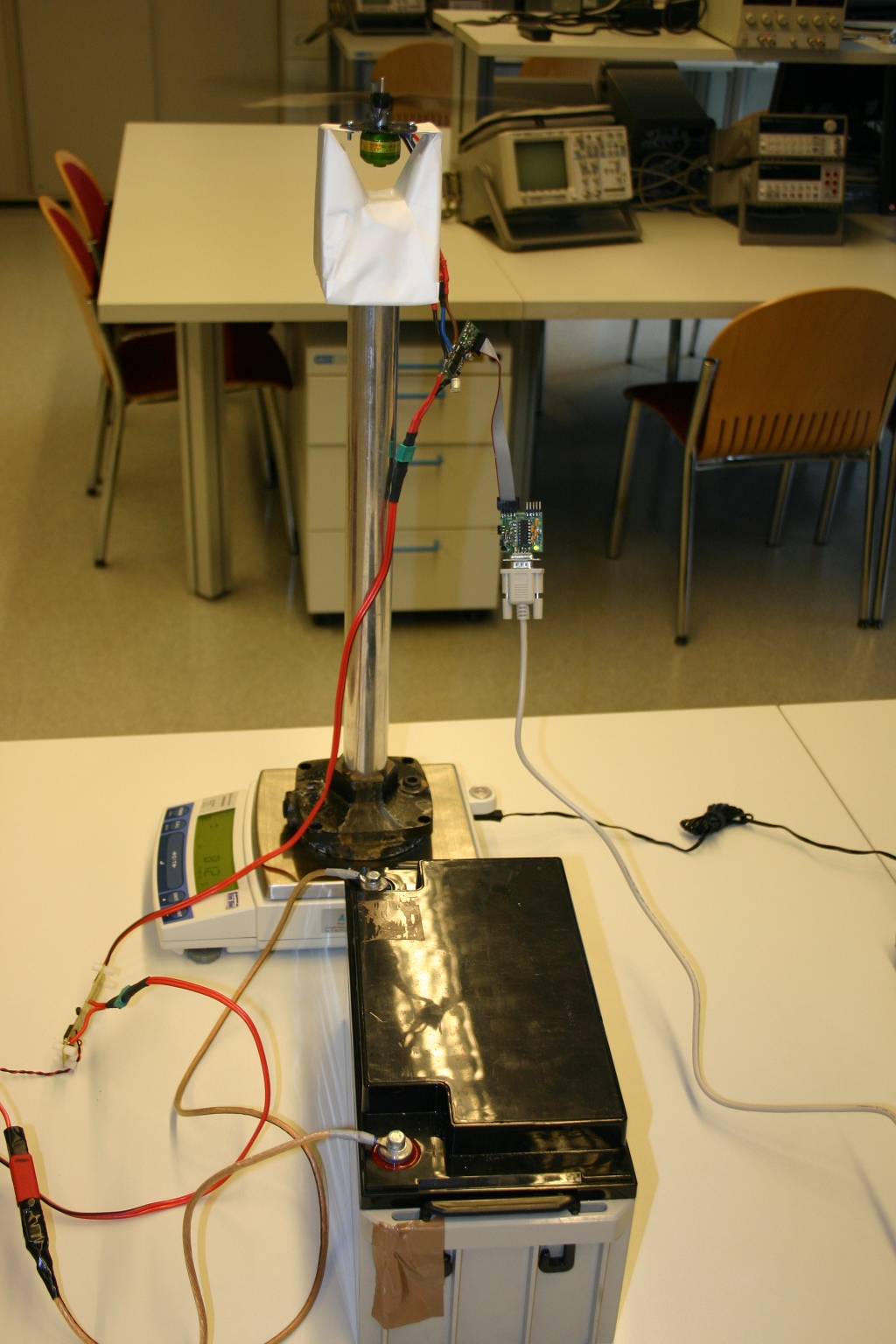

For the measure of the buoyancy force we use a weighing machine 🙂 (see gallery)

To measure the motor/prop. speed we used two different measuring methods.

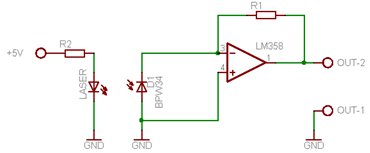

1. Laser module and a photodiode:

As you could see in the circuit diagram it is very high sophisticated 🙂

2. Via Back EMF (back electromotive force)

Back EMF is the voltage that pushes against the current which induces it. This voltage can be used to measure the motor speed.

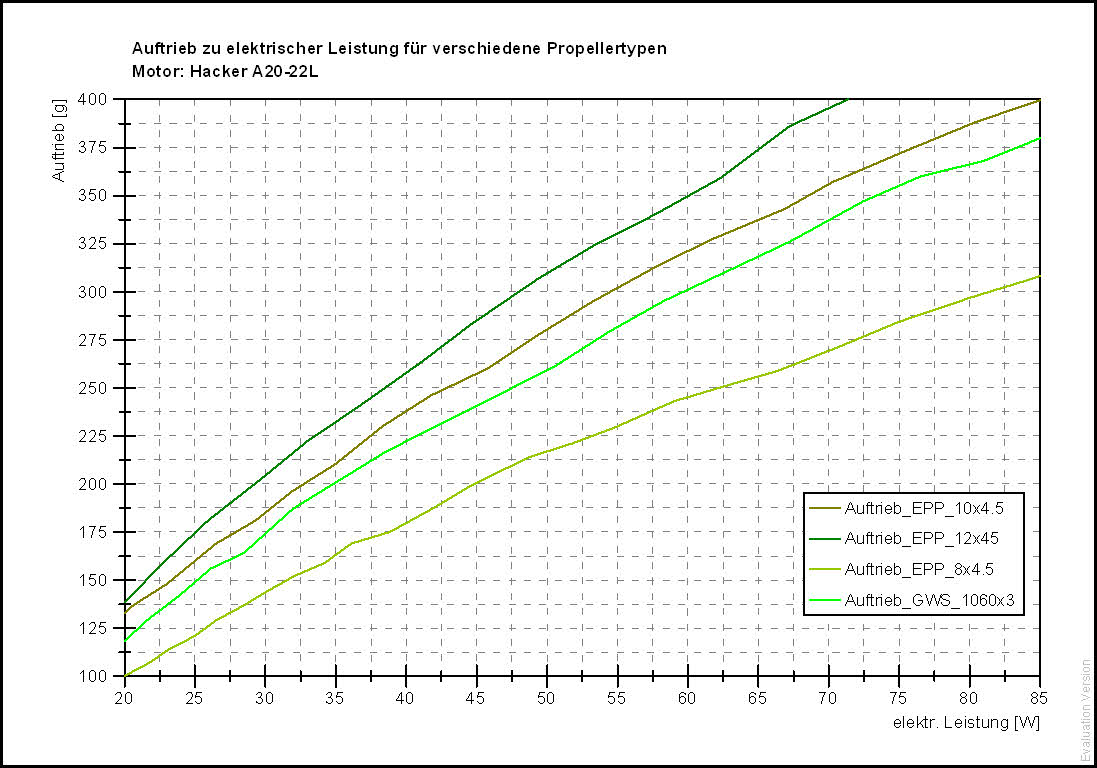

Some Results for the electric current versus buoyancy measurements:

Some Results for the Tau63 measurements:

Last but not least, Ladies and Gentleman let me introduce you the Test-Stand itself 🙂

hallo,

(ich hoffe, deutsch ist ok ?)

ich bastle an 4coptern rum, weil ich das in der schule als mechatronik-gegenstand benutzen möchte.

hab einen gebaut, fliegt auch, aber es fehlt an theoretischem unterbau.

-> die sprungantwort habe ich gesucht ! (für lange versuche fehlt mir die zeit).

es müßte doch möglich sein, z.b. als einfachsten fall für den höhenregler, einen “simulationsbaukasten” zu erstellen, um mit eingangsparametern (masse, motor-kennlinie, sprungantwortparameter) für jeden beliebigen copter den optimalen parametersatz für nen pid zu ermitteln. man müßte sich auf ein tool einigen, das jeder interessierte nutzen kann (labview ist zu teuer).

interesse an so einem projekt ?

HI

My name is Jose G Rodriguez, my background is mechanical engineering at Polytechnic University of Puerto Rico.

I’m very interested in this project, I will like to use your model to design a Propeller Test Stand for my Capstone project.

1. What tipe of electric motor did you use and if it was sensored ?

2. What is the maximum RPM to be use in this experiment?

3. The program use to do the calculations.?

4. Did you use a adapter interface to measure RPM,Torque and other type of measurment to analyse the propeller trust.?

5. If any matlab program where use?

6. Also, if you could give us any structural information about the design.

Hi Jose,

@Motor type,.. we used plain brushless motors without sensors. We build our own rpm measurement unit 🙂

@max rpm,…typical rpm for motors used with quadrocopters are around 3000-4500 rpm

@program,… we used labview (mxDAQ), own programming stuff

@adapter,… we measured the back EMK on the brushless controller, the boost with our high precision Libra, rpm via photo sensor. We didn’t acquired the torque.

@design, as you can see from the pictures on the blog,.. our teststand was completely low cost 🙂

regards,

Mario