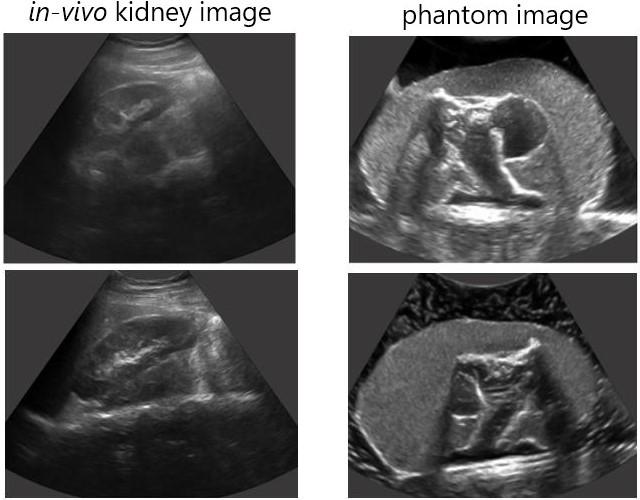

Imagine being a medical student, trying to perfect your skills in ultrasound imaging. You practice repeatedly, but the real organs you’re training on are not readily available, expensive, or have varying conditions. Now, imagine you had access to a realistic, durable, and affordable kidney model that could be used anytime, anywhere. This is the exact challenge that Mr. Moritz Wieser addressed in his bachelor project.

In modern medical education and device testing, organ phantoms are becoming indispensable. These models replicate the structure and function of real organs, providing a controlled environment for training and experimentation. Despite their growing importance, commercially available organ phantoms are often prohibitively expensive, less realistic in terms of imaging contrast, and lack the flexibility to meet diverse needs.

Recognizing these issues, Mr. Moritz Wieser embarked on a project to develop a more accessible and realistic alternative: a 3D-printed kidney phantom specifically designed for ultrasound imaging. First, he segmented the kidney and the renal pelvis from abdominal CT image of a healthy subject, using semi-automatic segmentation tools from 3D Slicer. Then, by combining advanced 3D printing technology with carefully selected materials, he sought to create a model that not only mimics the anatomical structure of a human kidney but also closely replicates its ultrasound imaging properties.

The results were promising. The agar-based phantom successfully simulated the structural and acoustic properties of a real kidney when imaged using ultrasound. Although there were some differences in contrast compared to a real organ, the overall performance was close enough to serve as a valuable tool for both training and device testing.

The work of Mr. Wieser highlights the potential of 3D printing technology in creating customized, cost-effective solutions for medical training and research. By developing a more accessible and realistic kidney phantom, this project represents a significant step towards improving the quality of ultrasound education and the development of medical devices.

In conclusion, this bachelor project demonstrates the power of innovation in medical technology. By leveraging 3D printing and carefully selected materials, Mr. Wieser has contributed to a more effective and affordable way to train future healthcare professionals and test medical devices. This project is a testament to the impact that well-designed, user-centred solutions can have on the field of medical education and beyond.

Yours,

MedTech @ FH Kärnten Team